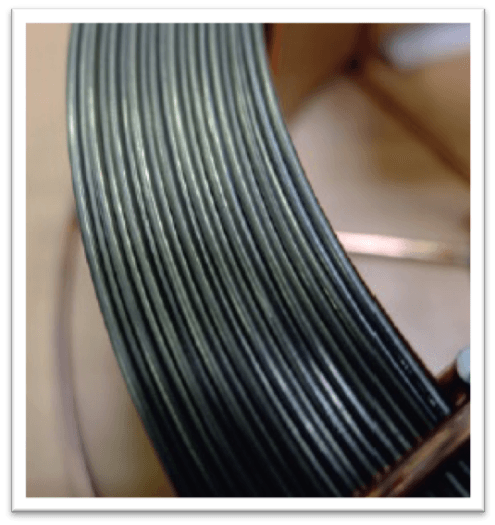

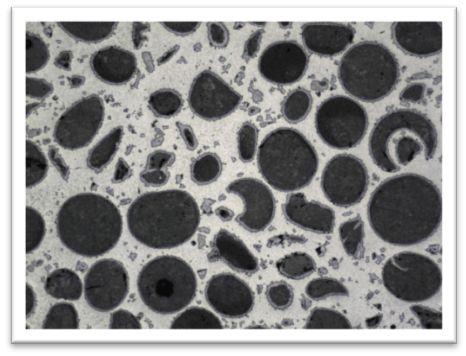

Metal-cored wire with spherical cast tungsten carbide (Spherotene®) in a Nickel-based matrix for optimum abrasion resistance in severe environmental conditions.

- The deposit provides very good resistance to wear

- The alloy system offers re-facing capability in all welding positions including vertical

- Re-application on worn tools can easily be done

- The low heat input helps reduce tungsten carbide particle dilution