Hardfacing Application Specialists

Laser Cladding and Welding Products and Consumables

LASERCARB

LASERCARB ®by TECHNOGENIA

LASERCARB ® Wear Resistance – Uniquely Engineered

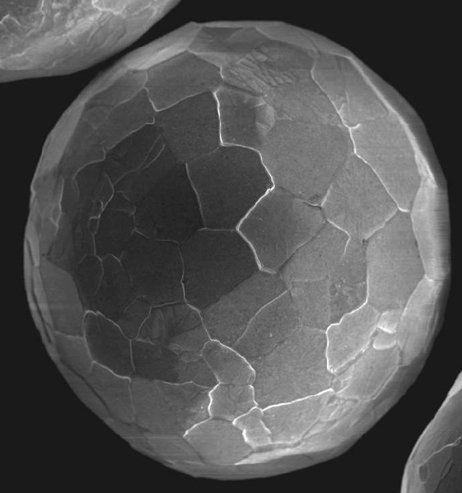

Technogenia, innovators of the Lasercarb hardfacing process, is strategically applying its’ proprietary Technolase® powders with Spherotene®, a spherical cast tungsten carbide, to extend component wear life against abrasion, corrosion and erosion in these industries:

- Oil & Gas

- Mining

- Tunneling

- Mixing Equipment

- Geodrilling

- Industrial

- Agriculture

- Construction

LASERCARB ® BENEFITS

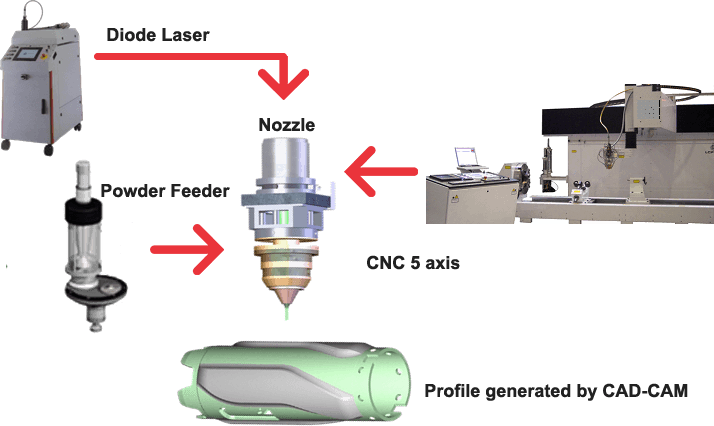

- CNC, 5-Axis automated laser for precise deposit

- Extremely high deposit efficiency

- High hardness factor 3000 HV, low heat affected zone (.060”)

- Virtually no porosity, minimal to no deformation

- High range of thickness deposit

- Numerous combinations of powders, application-specific

- Superior metallurgical bond

- Applied to Carbon steel, Stainless steel, Non-mag stainless steel

- Can be applied to virtually any profile

THE LASERCARB ® PROCESS

Utilizing a CNC controlled, high energy diode laser, a precise, metallurgical weld deposit is applied to the component surface to protect against abrasion, corrosion and erosion. The application-specific Technolase powder matrix in combination with our Spherotene® cast tungsten carbide provides a hardness factor of 3000Hv + 500.

PRIMARY APPLICATIONS

- Oil & Gas:

Stabilizers, Adjusting rings, Bearings (OD and ID) see Patent Details No. 8,795,794 B2, Bearing housings, Drive shafts, Mandrels, Non-mag stabilizers, MWD and LWD tools

- Mining:

Bits, Bearings, Bearing surfaces

- Tunneling:

Bits, Bearings, Shafts

- Mixing Equipment:

Impellers, Mixing blades

- Geodrilling:

Bits, Shafts, Bearing surfaces

- Industrial:

Pumps, Impellers, Shafts, Bearings

- Agriculture:

Soil sample tools, Scrapers, Augers

- Construction:

Bearings, Bearing surfaces, Drive shafts

RECOMMENDED TYPES OF BASE MATERIALS

- Carbon steel

- Stainless steel

- Non magnetic stainless steel

- Duplex, Super Duplex

SPECIFICATIONS

LASERCARB ® SPECIFICATIONS

- Deposit thickness: 0.015" to 0.150"

- Greater thicknesses - Please contact us.

- Capacities: Length up to 40ft.-Diameter up to 20" Weight 10,000 Lbs.

- Due to their extreme hardness, LaserCarb® deposits cannot be machined except by grinding with diamond tools.

LASERCARB ® I.D SPECIFICATIONS

- Deposit thickness: 0.015" to 0.150"

- Capacities: Length up to 40" long

- Minimum diameter 2"

- Weight 6,000 Lbs.

TYPES OF COATINGS

Technolase® powders combine the high hardness of Spherotene® with the unique properties of application-specific matrices to increase anti-wear and erosion protection to the surface of virtually any tool or component profile.

| Technopowder | Thickness | Similar to | Application |

|---|---|---|---|

| Technolase® 40S | up to 0.050 | 40% - 40 Hrc NiCr Matrix 60% - Spherotene® | Hardfacing, erosion and abrasion protection |

| Technolase® 20S | up to 0.150 | 40% - 20 Hrc NiCr,Matrix 60% - Spherotene® | Hardfacing, erosion and abrasion protection |

| Technolase® 30S | up to 0.150 | 40% - 30 Hrc NiCr,Matrix 60% - Spherotene® | Hardfacing, erosion and abrasion protection |

| Technolase® 50S | up to 0.150 | 40% - 50 Hrc NiCr,Matrix 60% - Spherotene® | Hardfacing, erosion and abrasion protection |

| Technolase® 60S | up to 0.150 | 40% - 60 Hrc NiCr,Matrix 60% - Spherotene® | Hardfacing, erosion and abrasion protection |

| TP 316-316L | unlimited | SS 316 - SS 316L (Austenitic SS) | Build up and/or Repair |

| TP 431 | up to 0.150" | SS 431 (martensitic SS) | Repair, wear application |

| TP 245 | up to 0.060" | Stellite 1 | Hardfacing, erosion and abrasion protection |

| TP 255 | up to 0.150" | Stellite 6 | Hardfacing, erosion and abrasion protection |

| TP 265 | up to 0.150" | Stellite 12 | Hardfacing, erosion and abrasion protection |

| TP 275 | up to 0.150" | Ultimet | Impact resistance, high toughness |

| TP 625 | unlimited | Inconel 625 | Corrosion resistance |

| TP 276 | unlimited | Hastelloy C276 | Corrosion resistance |

| TP Fe 7 | up to 0.150" | Tool steel | Impact resistance, abrasion, erosion |

| TP diam | up to 0.150" | composition: upon request | High erosion and abrasion resistance |

| TP Titanium | up to 0.150" | Ti-6Al-4V | Build up and/or repair |

CONTACT INFO

Technogenia

Phone: +1 936 441 4770

Fax: 936 539 4760

Technogenia Lasercarb Oklahoma, Inc.

Phone: +1 405 470 3350

Fax:

405 470 3362

CONTACT US

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

© 2024

All Rights Reserved | Technogenia USA